Fraunhofer ISE nails 25.9% with III-V/Si tandem solar cell

Solar Impulse in fluffy clouds

Thank you for visiting – ❤ with gratitude! Fave if you like it, add comments below, get beautiful HDR prints at qualityHDR.com.

Solar Impulse, a solar aircraft just landed at Moffett Federal Airfield at NASA Ames in Mountain View, California. Hurray!

Today we went to San Francisco to watch the aircraft fly over the Golden Gate Bridge. We had a nice picnic a Crissy Field. Solar Impulse was flying quite high, this is a tele-zoom shot.

Founders Bertrand Piccard and André Borschberg want us to use more clean energies. Or in their word, push the transition to renewable energy resources. Very inspiring!

The aircraft has a wingspan bigger than a Boeing 747, but weights just 2 tons instead of 400 tons. More info on this historic flight at www.solarimpulse.com

I processed a balanced HDR photo from a RAW exposure.

— © Peter Thoeny, CC BY-NC-SA 4.0, HDR, 1 RAW exposure, NEX-6, _DSC6003_hdr1bal1a

By PeterThoeny on 2016-04-23 17:18:05 Fraunhofer ISE nails 25.9% with III-V/Si tandem solar cell

Fraunhofer ISE nails 25.9% with III-V/Si tandem solar cell

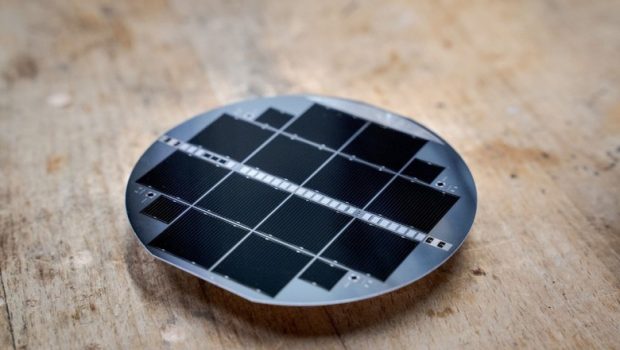

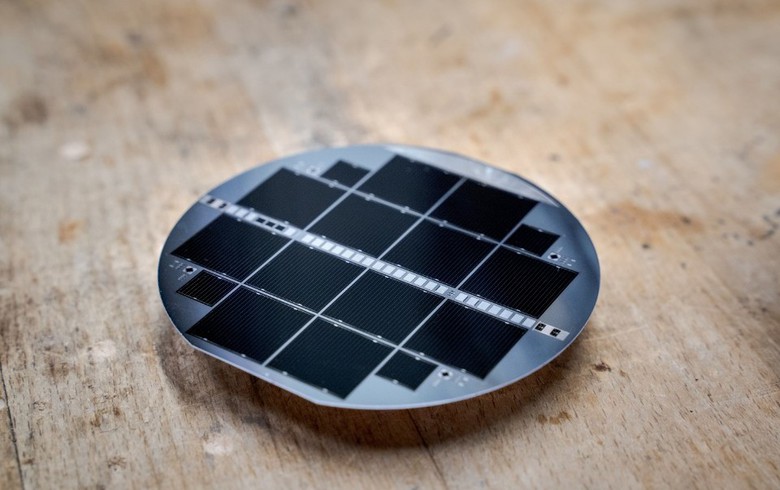

August 11 (Renewables Now) – The Fraunhofer Institute for Solar Energy Systems ISE (Fraunhofer ISE) has reached a record 25.9% efficiency for a multi-junction solar cell, in which micrometer-thin layers of III-V compound semiconductors are directly grown on silicon wafers.

In this type of tandem cells, the silicon layer absorbs the infrared part of the spectrum, while the layers of III-V compound semiconductors made of elements from groups III and V of the periodic table absorb ultraviolet, visible and near-infrared light.

The institute holds the world record efficiency of 34.1% (new 34.5%) for a photovoltaic (PV) cell in which the III-V layers are transferred from a gallium arsenide to a silicon substrate and connected by wafer bonding. Such cells, however, are expensive so Fraunhofer ISE worked for several years on more direct manufacturing processes.

In the new tandem solar cell, the III-V layers were grown directly on a silicon wafer, developed by Danish company Topil in the European SiTaSol project, instead of on a chemo-mechanically polished substrate as in previous attempts. Fraunhofer ISE noted that after sawing, the wafer went only through inexpensive grinding and etching processes.

Future work will focus on boosting the efficiency further up and achieving faster layer deposition, with higher throughput, in order to improve the cost-effectiveness of the production process.